Investment Casting

Investment casting, a precision manufacturing method, produces complex metal parts with fine details. It involves creating a wax pattern, encasing it in ceramic, melting the wax, and pouring molten metal into the mold. This process ensures intricate shapes and is used in industries where precision is required. Altair Inspire Cast is a simulation software tailored for casting processes. It aids engineers in optimizing casting designs by predicting potential defects like porosity, shrinkage, and flow issues. By simulating and analyzing these factors, it enables efficient and cost-effective production of high-quality metal components in industries.

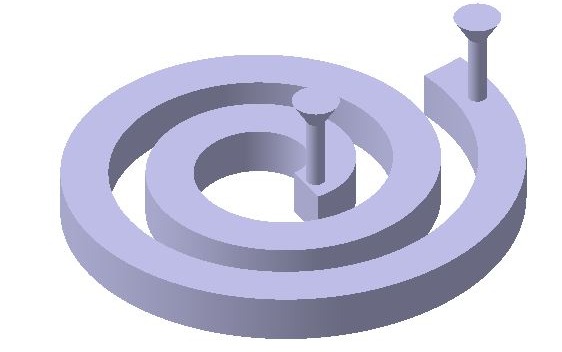

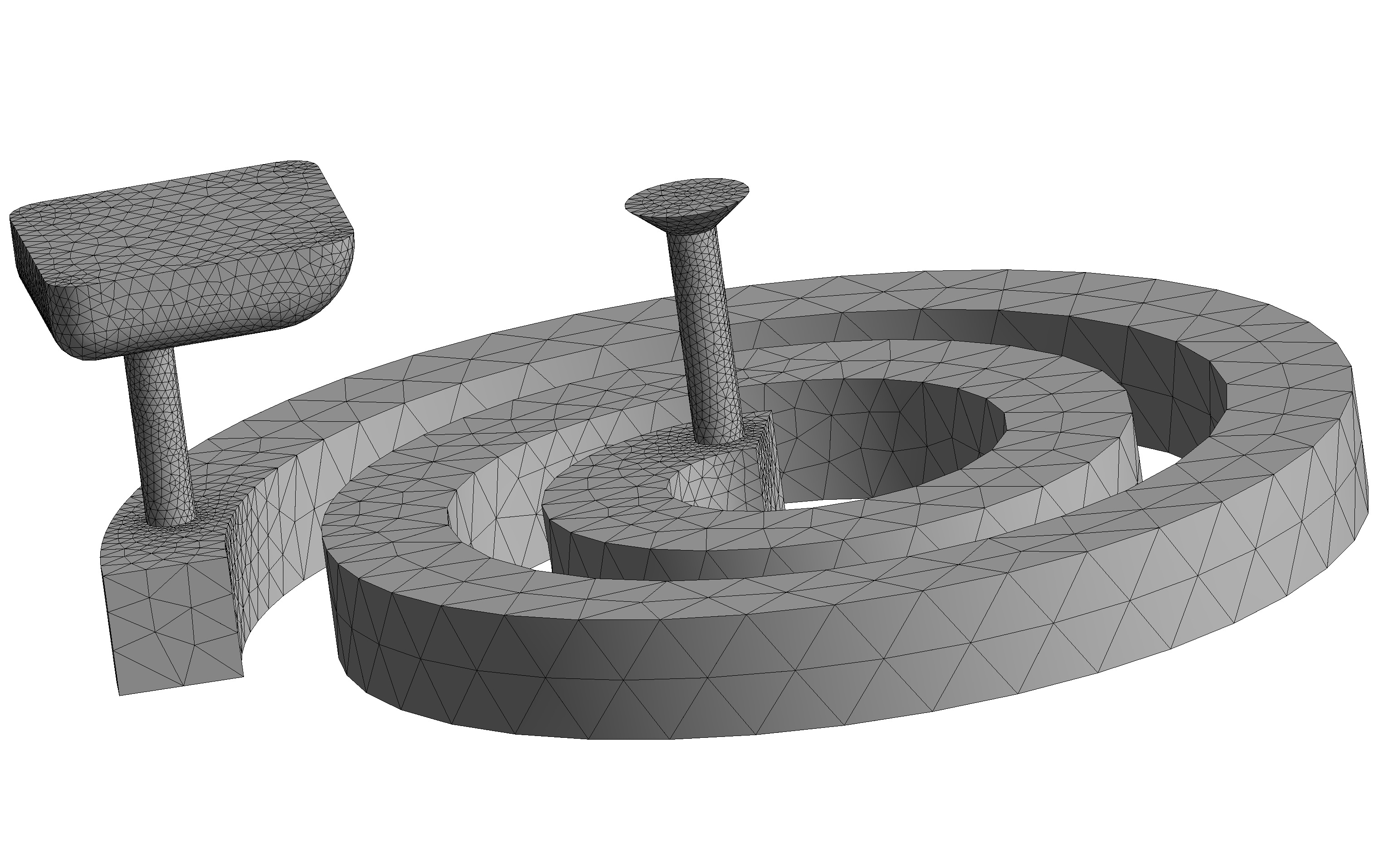

Computational Model

Meshing of the Model

Temperature variation during Filling

Liquid Fraction variation during Filling

Temperature variation during Solidification

Liquid Fraction variation during Solidification

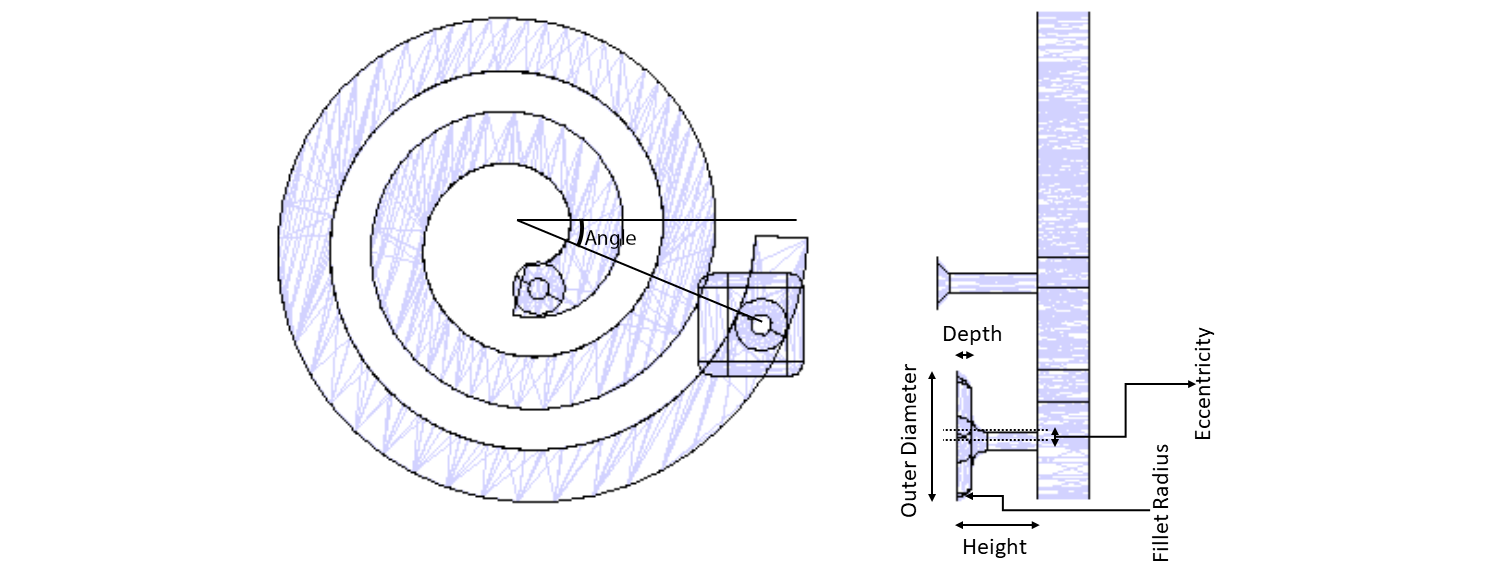

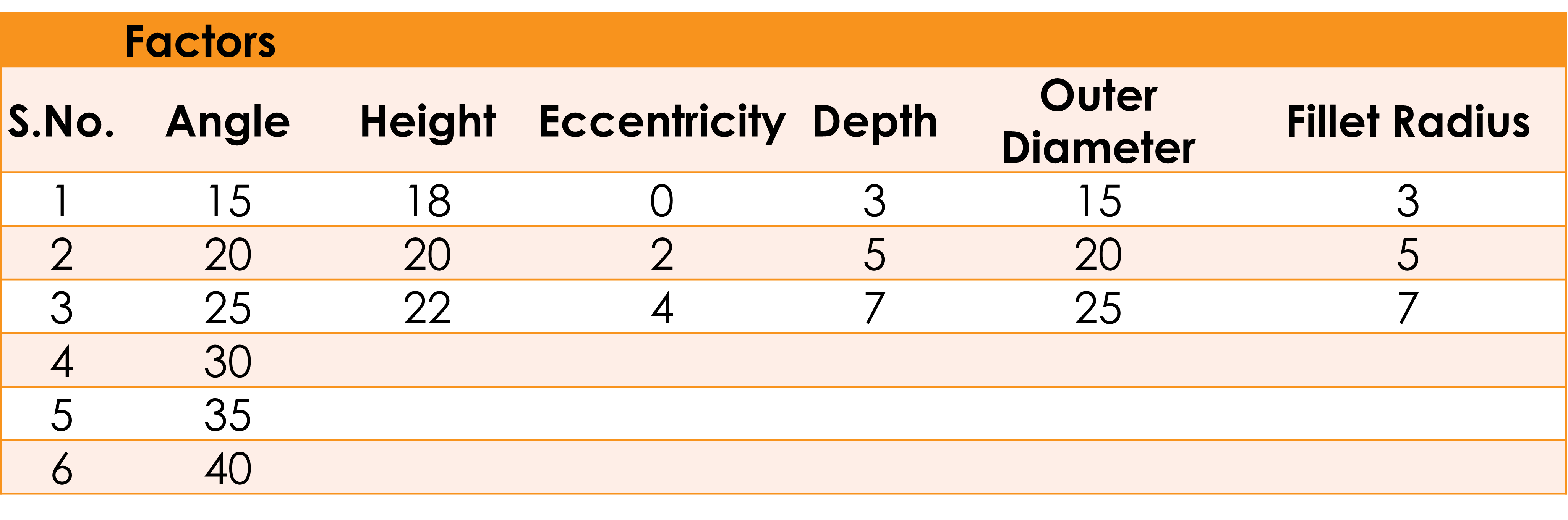

Design of Experiments (DOE)

A Design of Experiments (DOE) study involves systematically planning and conducting experiments to gather data in an efficient and structured manner. Its purpose is to explore relationships between variables, optimize processes, or make informed decisions based on empirical evidence. In this case, we have considered six factors and one output variable. Those six factors are: Angle, Height, Eccentricity, Depth, Outer Diameter and Fillet Radius. The output selected here is the time taken for solidification of the material.

Shape Analysis

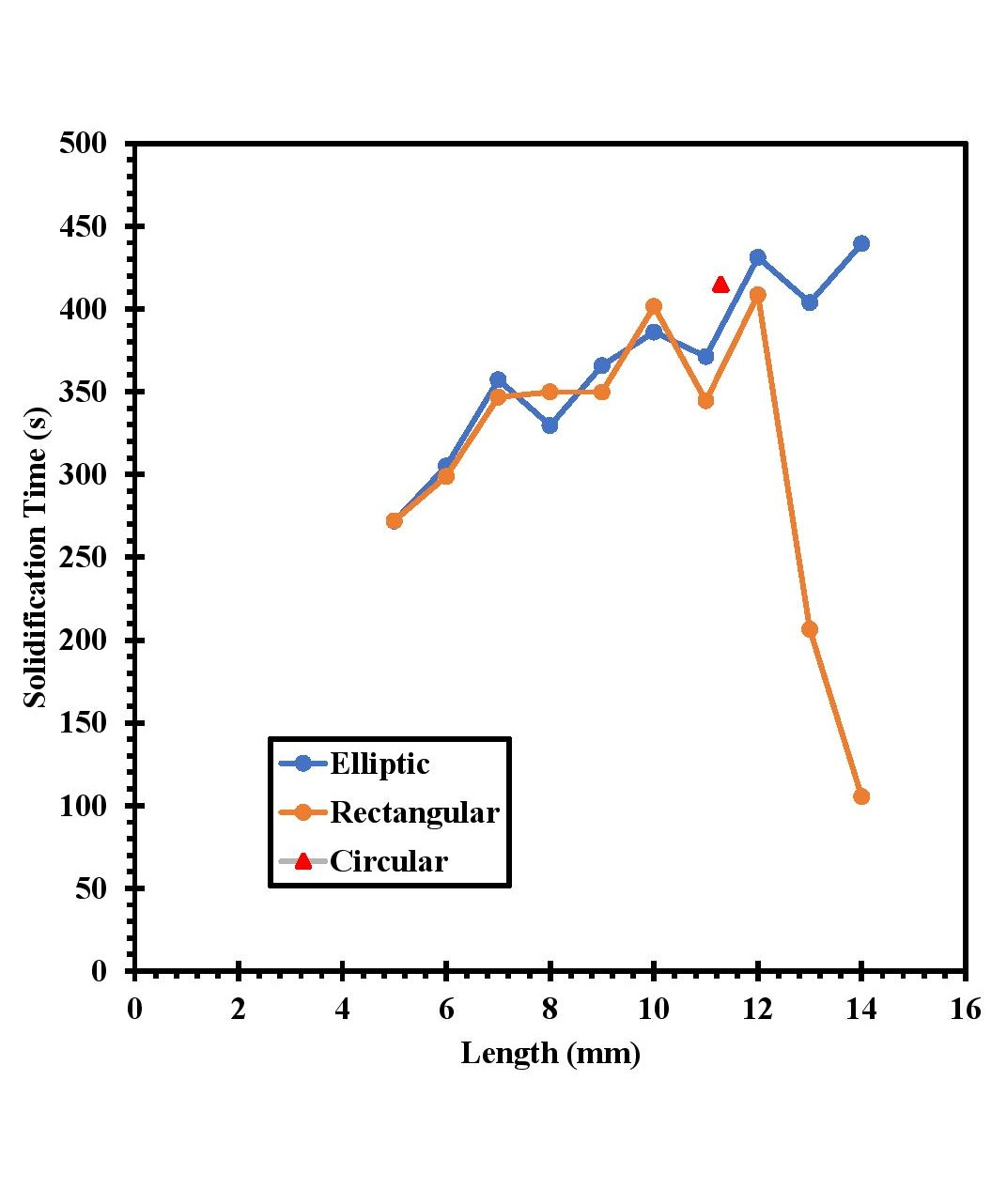

Shape analysis has been conducted based on the results from the previous studies and the cross section shape is changed from rectangular,

square, circular and elliptical as shown below. Cross sectional area has been kept constant to ensure the volume of the cast remains same.

We observed that the base of the cross section of the mold needs to be wider irrespective of its shape. However, manufacturing an

elliptical or circular cross sectioned mold is a challenging task and it requires special techniques to achieve the expected results.

So, it would be a wiser option to go with the rectangular cross section as it is easy to manufacture and can be customized to our needs

without much effort and we can obtain better results with rectangular cross-sectional mold.

Shape analysis has been conducted based on the results from the previous studies and the cross section shape is changed from rectangular,

square, circular and elliptical as shown below. Cross sectional area has been kept constant to ensure the volume of the cast remains same.

We observed that the base of the cross section of the mold needs to be wider irrespective of its shape. However, manufacturing an

elliptical or circular cross sectioned mold is a challenging task and it requires special techniques to achieve the expected results.

So, it would be a wiser option to go with the rectangular cross section as it is easy to manufacture and can be customized to our needs

without much effort and we can obtain better results with rectangular cross-sectional mold.